Our customer Calvin from Korea wants to sheet two unique materials.(Click here to view shipping news)

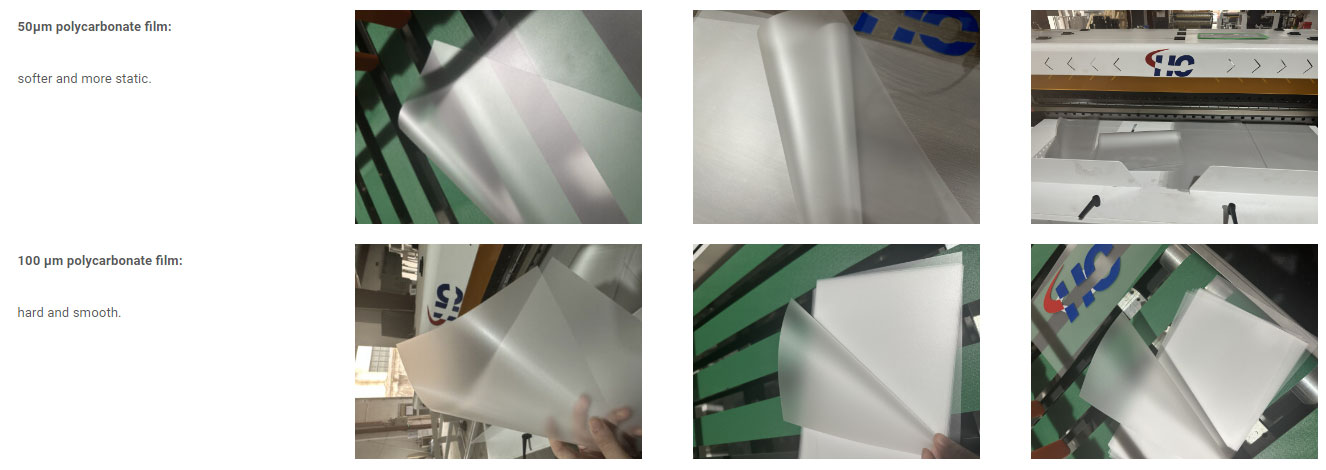

These two materials are 50μm polycarbonate film and 100μm polycarbonate film.

During the test machine, we found that the conveyor belt could transport 100gsm material perfectly. However, the 50 μm material is too soft and generates a lot of static electricity. If use a conveyor transport, the material will become messier.

We try to let customer sort materials easily. So the engineers designed two usages model.Table stacker for thin film, conveyor stacker for the thick film.

Improving and customizing the machine usually takes more time.

From confirming the order to updating the machine and finally running it. It took us just one month until this material was ready to cut perfectly. Hochint machinery is keep improving in quality with every machine.

Added a high-speed electrostatic eliminator specifically for 50 micron films

Adopt wire feeding to make the film more smoothly when transferring

By lengthening the bottom plate, the movable distance of the conveying table is extended, so that it can be used in two ways

GET A QUOTE