• Cutting type: Guillotine cutting knife

• Cutting speed: 30-180 cuts/min

• Stack type: Table stacker

• Suitable Materials: kraft paper, art paper, silicon paper, film, Nonwoven

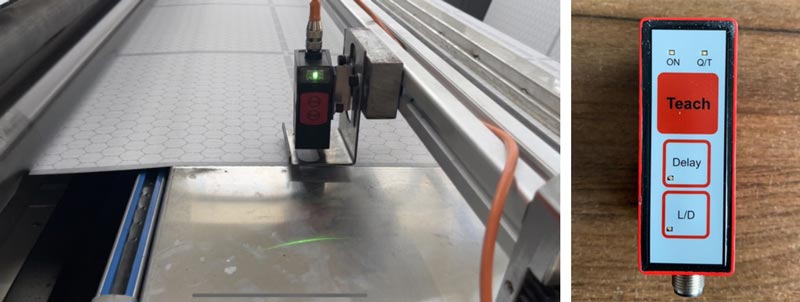

• Color register: German LEUZE color code sensor

1. Fully automated design, reducing manual intervention, improving production efficiency and consistency. Equipped with automatic feeding, cutting and stacking functions.

2. Equipped with an advanced cutting system, it can accurately cut the paper roll into the required size to ensure the consistency of paper size and quality.

3. The design supports quick replacement of cutting tools to reduce downtime.

4. Equipped with an intelligent control system and a touch screen interface, it is easy to operate, can monitor the production status in real time, and adjust the parameters to adapt to different paper specifications and production requirements.

5. It can handle paper rolls of various specifications, automatically complete the cutting, sorting and stacking of the rolls, and can adapt to different sizes and types of paper.

6. Support setting the cutting length to ensure that the size of each paper meets the specification requirements.

7. Usually equipped with an automatic stacking device, which can automatically and neatly stack the cut paper.

8. Adopt energy-saving technology and efficient drive system.

9. Suitable for all types of paper, including newsprint, writing paper, and coated paper.

√ 20-500g various paper (kraft paper, art paper, silicon paper, coated paper, newsprint paper and so on)

√ Sticky label (adhesive paper)

√ Various laminates (film to film, film to paper)

√ Film thickness≥30 micron

√ Nonwoven and so on

This machine is suitable for cross cutting jumbo rolls, like papers, adhesive sticker, thick plastic film, or some laminates material, into sheets of any needed size with high speed and high precision. It is the ideal equipment for paper making, plastic, printing and food packaging industry.

Shafted Unwind with Table Stacker

|

Model |

HKA-800 |

HKA-1100 |

HKA-1400 |

|

Max. loading jumbo roll width (mm) |

800 |

1100 |

1400 |

|

Max. loading jumbo roll diameter (mm) |

Φ1400 |

Φ1400 |

Φ1400 |

|

Max. loading jumbo roll weight (kg) |

1000 |

1000 |

1000 |

|

Unwind paper tube inner core diameter |

3” (76mm) |

3” (76mm) |

3” (76mm) |

|

Web guide sensor |

Ultrasonic sensor |

Ultrasonic sensor |

Ultrasonic sensor |

|

Cutting length (mm) |

20-2000 |

20-2000 |

20-2000 |

|

Cutting precision (mm) |

±0.2 |

±0.2 |

±0.2 |

|

Cutting speed (cuts/min) |

30-180 |

30-180 |

30-180 |

|

Edge trimming system |

Blowing fan |

Blowing fan |

Blowing fan |

|

Cutting thickness |

20-500gsm |

20-500gsm |

20-500gsm |

|

Total power (kw) |

8 |

10 |

12 |

|

Power supply |

380V, 3P, 50HZ |

380V, 3P, 50HZ |

380V, 3P, 50HZ |

|

Air supply |

0.6-0.8 Mpa, 0.8m3/Min |

0.6-0.8 Mpa, 0.8m3/Min |

0.6-0.8 Mpa, 0.8m3/Min |

|

Weight(kg) |

2300 |

2500 |

2700 |

|

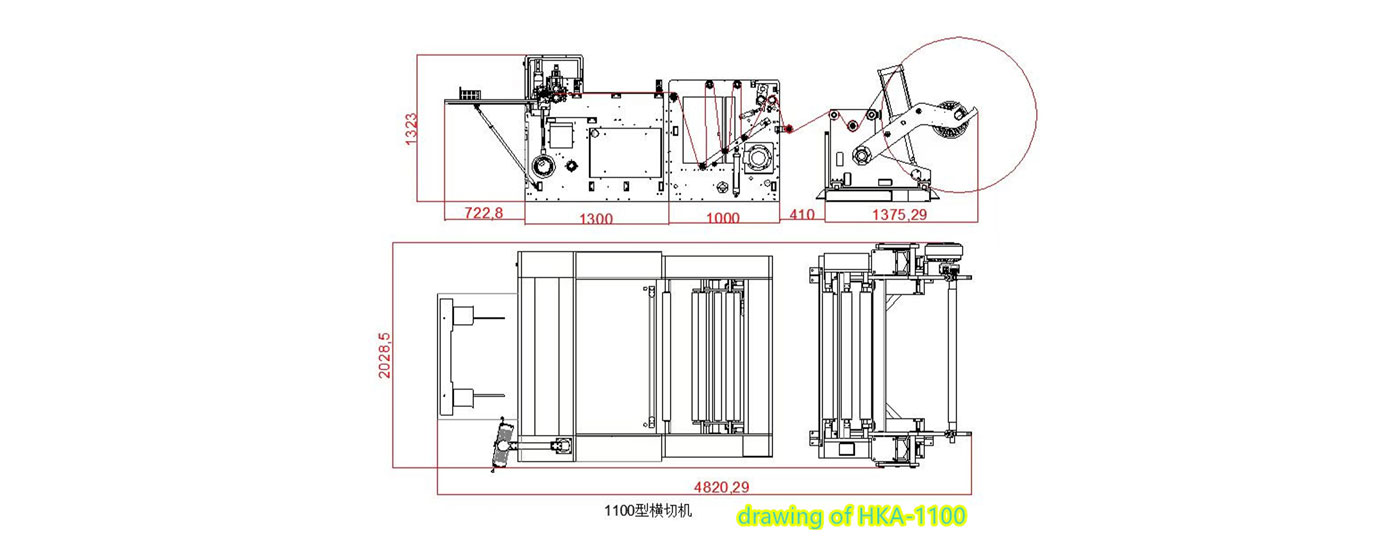

Overall Dimension(mm) |

4800*1750*1350 |

4800*2050*1350 |

4800*2350*1350 |

1. Integrated Shafted unwind

> We adopt the Shafted unwind unit for jumbo roll loading, with auto cylinder lifting.

> Cylinder control One-click pneumatic lock for unwind shaft.

> Two pcs Φ200 cylinder driven the clip arms lifting and down.

> Magnetic powder brake 20kg *1 pc for unwind tension control.

> Machinery material: Cast Iron Steel and Steel Plate 20mm thick fuselage.

> Standard spec:

Max. Reel diameter: 1400mm

Max. Reel weight: 1000kg

Inner core size: 3” (76mm)

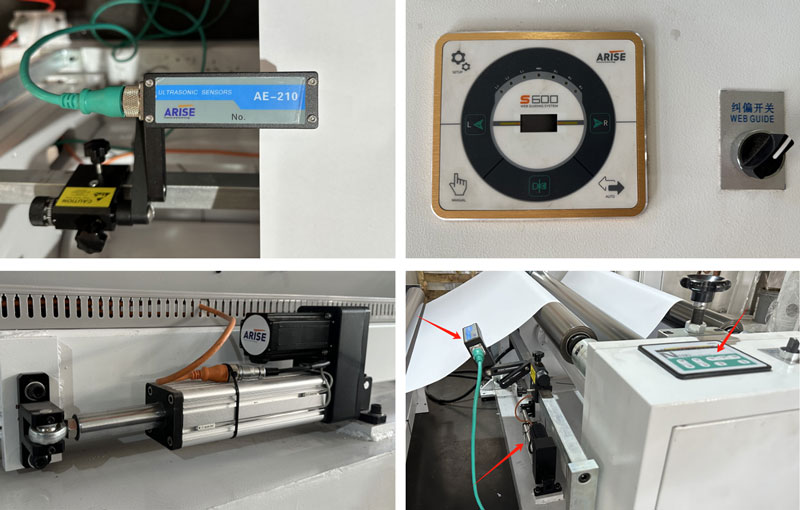

2. Web guide system.

> Equipped an Arise web guide system for edge detection. Ensure the material feeding is exact.

> Web guide system with both Automatic and manual control

> High Precision ultrasonic sensor which easily and fast detects various web edge.

> Include ultrasonic sensor, controller and correct motor.

3. Traction System

> Traction use rubber roller with TPU material driven for both thin and thick paper. (20-500gsm)

> Nip rubber roller with adjustable pneumatic control for perfect tension control.

> Infront traction roller with Servo motor (motor driver) control for high precision cut and back traction roller with motor driven for feeding material.

4. Dance roller

> Pneumatic dancer roller unit for auto speed varied and assures that the stable web feeding under high-speed running.

> Encoder for dancer roller to detect the position accurately which is displayed on touch screen, and the traction speed can be adjusted based on the position of dancer roller.

> Dancer roller tension display on touch screen and adjustment.

5. Cutting unit

> Heavy-duty casting knife holder, bottom knife is fixed and upper blade is movable.

> Servo motor with driver to control the cutting length of web with high precision.

> High-speed steel cutting knife (2 sets) guarantees perfect cutting quality and a long usage life (one set 5- 6 years usage life and grind knife every 6-8 months)

> Brake AC motor driving the cutting knife up-down movement on the Hiwin guiding rails is essential for rapid stopping and holding action.

> Anti-static for double side treatment.

> Rotary shear knife for slitting before cross-cutting

6. Table Stacker

> The angle and height of the table can be adjusted.

> Table size can be customized.

7. Electrical Unit

> > All electrical appliances comply with China 3C certificate standard. Safe and long-lasting.

> The layout of the electronic control board has been carefully designed, arranged neatly, and occupies a small area.

8. Touch Screen with PLC system

> Colorful touch-screen and PLC (Panasonic, Japan).

> Chinese, English language on touch screen

> Cutting length and cutting quantity setting function.

> Problem diagnosis function on touch screen, if any problems occur, you can check I/O page to find it.

1. German LEUZE color code sensor

> Top world brand color code that could correctly follow the eye marks printing and cut with high precision

2. Anti-curve device

> Anti-curve device for thick material.

> Adjustable angle by manual

3. Auto-Lifting Table Stacker

> Automatic lifer(up-down) for table

GET A QUOTE