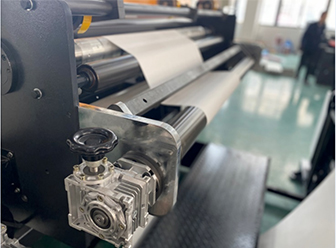

The main function of a Paper Slitting Rewinding Machine is to slit wide rolls of paper into narrower widths and then rewind the slit paper onto separate cores to form individual rolls.

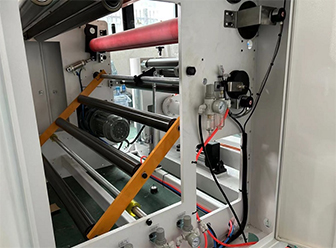

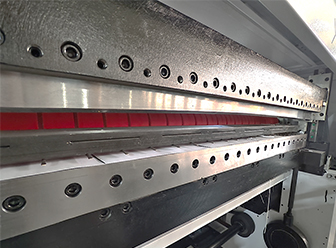

Paper Slitting Rewinding Machine is mainly used to slitting and rewinding wide rolls to form finished paper rolls or film rolls that meet specific specifications and requirements. It uses PLC computer programming technology and human-machine interface operation to automatically complete the processes of trimming, slitting, splicing and rewinding of base paper, thereby improving production efficiency and product quality. It is widely used in papermaking, printing, packaging and other industries and is an indispensable and important equipment in these industries.

The main function of a Paper Slitting Rewinding Machine is to slit wide rolls of paper into narrower widths and then rewind the slit paper onto separate cores to form individual rolls.

Generally speaking, the speed of high-speed paper slitting and rewinding machines is between 400 and 600 m/min, but this will also vary depending on factors such as the purpose of the machine and the set working parameters. Currently, we can also customize higher-speed equipment for you

Paper rolls such as newsprint, offset paper for printing, kraft paper for packaging, tissue paper, and label paper are suitable for the Paper roll Slitting Rewinding Machine.

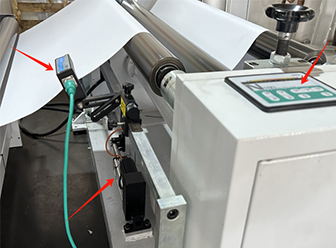

Each Paper Slitting Rewinding Machine is equipped with an ultrasonic sensor that can automatically correct and reduce errors.

The general load-bearing range of our slitting and rewinding machines is 800-3500kg. At present, if you need equipment with a stronger load-bearing capacity, we can also customize it for you.

GET A QUOTE