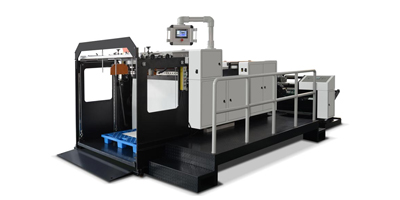

The roll-to-sheet cutting machine is a cornerstone of modern manufacturing, enabling industries to convert large rolls of materials—such as paper, film, textiles, or composites—into precisely sized sheets. Achieving high precision and efficiency in this process requires a deep understanding of the technology, meticulous control of operational variables, and proactive maintenance practices. This article explores the critical aspects of optimizing roll-to-sheet cutting systems for superior performance.

At its core, a roll-to-sheet cutting machine integrates mechanical, electrical, and software systems to unwind, tension, cut, and stack materials. Key components include:

Unwinding System: Controls the release of the roll material with minimal tension fluctuations.

Tension Control System: Uses sensors and servo motors to maintain consistent material tension, preventing stretching or wrinkling.

Cutting Mechanism: Employs rotary blades, guillotine knives, or laser cutters synchronized with material feed speed.

Stacking Unit: Automates sheet collection to ensure uniformity and reduce manual handling.

Modern machines leverage PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) systems for real-time adjustments, while advanced models incorporate AI-driven algorithms to predict and compensate for material behavior.

Tension Control: Uneven tension causes material slippage or deformation, leading to misaligned cuts. Closed-loop tension systems with load cells or dancer rollers are essential for stability.

Material Properties: Variations in thickness, elasticity, or moisture content impact cutting accuracy. Pre-cut sensors can detect irregularities and adjust blade pressure or speed dynamically.

Tooling Maintenance: Worn blades or misaligned cutting heads degrade precision. Regular sharpening, alignment checks, and using hardened steel or ceramic blades extend tool life.

Calibration: Daily calibration of feed rollers, sensors, and cutting units ensures dimensional accuracy. Laser-guided alignment tools are increasingly used for micron-level precision.

Operator Skill: Training operators to interpret machine diagnostics and troubleshoot in real time minimizes human error.

Golden parameter combination

| Material type | Cutting speed (m/min) | Blade pressure (N) | Feed tension (N) |

| Copper foil | 10-15 | 200-300 | 50-80 |

| Corrugated paper | 30-40 | 800-1000 | 200-300 |

| PVC film | 15-25 | 150-200 | 30-50 |

Automated Material Handling: Integrate automated roll loaders and stacking systems to reduce downtime between batches.

Smart Nesting Software: Use AI-powered nesting algorithms to maximize material utilization and minimize waste.

Real-Time Monitoring: IoT-enabled sensors track Roll-To-Sheet Cutting Machine performance metrics (e.g., vibration, temperature) to preempt bottlenecks or failures.

Preventive Maintenance Scheduling: Plan maintenance during non-production hours to avoid disruptions. Track component wear using predictive analytics.

Standardized Workflows: Implement SOPs (Standard Operating Procedures) for setup, changeovers, and quality checks to ensure repeatability.

Routine Maintenance Tasks:

Daily: Clean debris from blades and rollers; inspect pneumatic systems for leaks.

Weekly: Lubricate moving parts; validate sensor accuracy.

Monthly: Replace worn belts or bearings; recalibrate tension controls.

Common Issues and Solutions:

Misaligned Cuts: Check blade alignment and tension settings; verify material tracking sensors.

Wrinkled Sheets: Adjust tension control or reduce feed speed; inspect roller surfaces for damage.

Servo Motor Errors: Diagnose electrical connections or encoder malfunctions; reset PLC parameters.

Proactive Strategies:

Maintain a log of maintenance activities and performance trends.

Use OEM (Original Equipment Manufacturer) parts for replacements.

Train technicians in advanced diagnostics and firmware updates.

Common fault quick reference manual

| Fault phenomenon | Possible cause | Solution steps |

| Cutting burrs | Blade wear/insufficient pressure | Replace blade + increase pressure by 10%-15% |

| Dimension deviation exceeds ±1mm | Feed roller slips/encoder failure | Clean roller surface + restart encoder calibration procedure |

| Abnormal machine noise | Bearing wear/loose screws | Stop the machine to check bearing clearance + tighten all connectors |

| Sensor false alarm | Surface stains / installation offset | Wipe sensor with alcohol + recalibrate installation angle |

Precision and efficiency in roll-to-sheet cutting depend on harmonizing advanced technology with disciplined operational practices. By investing in robust tension control systems, optimizing workflows through automation, and adhering to rigorous maintenance protocols, manufacturers can achieve consistent quality, reduce waste, and boost productivity. As industries demand faster turnaround and tighter tolerances, continuous innovation in machine design and data-driven process management will remain pivotal to staying competitive.

GET A QUOTE