In the realm of industrial manufacturing, slitter rewinder machines play a pivotal role in processing wide rolls of materials into more manageable, customized widths. These versatile machines are essential across various industries, including paper, packaging, plastics, textiles, and metal processing. This article will delve into what slitter rewinding machines are, their applications, the key role of paper slitting rewinding machines, how the slitting process works, and the different types of these machines.

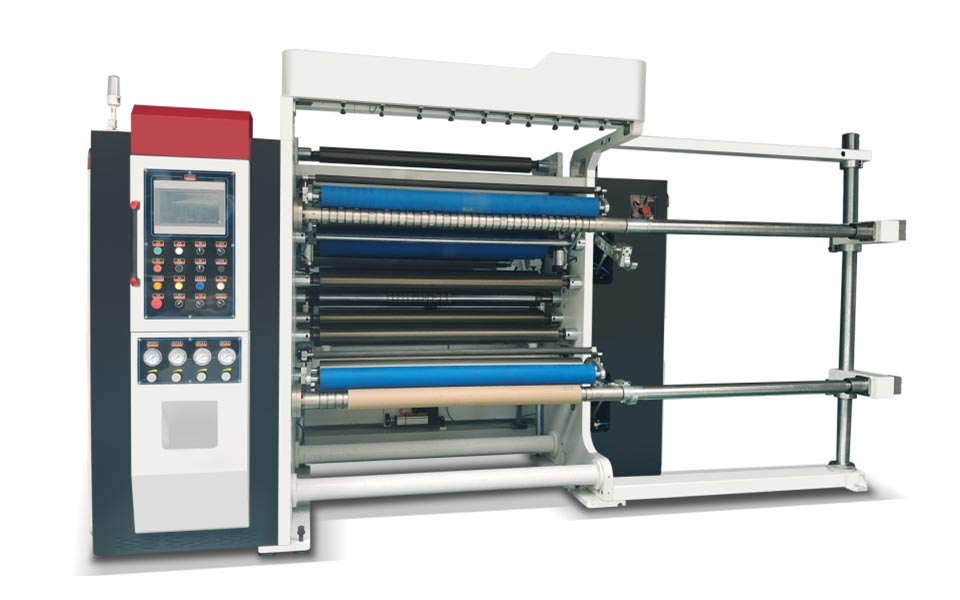

A slitter rewinder machine is a specialized industrial equipment designed to take a large parent roll of material and cut it into multiple narrower rolls, known as daughter rolls, while simultaneously rewinding them into neat, uniform packages. The primary function is to convert wide rolls into specific widths required for downstream applications, ensuring precision, efficiency, and consistency in material handling.

These machines are used in a wide array of industries. In the paper industry, they transform large reels of paper into rolls suitable for printing, packaging, or tissue products. In the packaging sector, they process plastic films, aluminum foils, and laminates into the correct widths for making bags, labels, or flexible packaging. Textile manufacturers use them to slit and rewind fabrics, non-wovens, and synthetic materials for further processing into garments, upholstery, or industrial textiles. Even in the metal industry, slitter rewinders are employed to cut thin metal sheets or foils into precise widths for applications like electronics, automotive, and construction.

The applications extend beyond just width adjustment. They also handle tasks such as removing defects from the material during the slitting process, applying adhesives or coatings, and ensuring the quality of the final rolls through tension control and edge trimming.

In the paper industry, the paper slitting rewinding machine is a cornerstone of the production process. Let's explore its key roles:

1. Converting Raw Material into Marketable Products

Paper mills produce large parent rolls of paper, often several meters wide, which are not directly usable for most end - applications. Paper slitting rewinders cut these large rolls into smaller widths suitable for different uses. For example, they can convert a wide roll of newsprint into narrower rolls that fit standard printing presses, or transform a large roll of kraft paper into the widths needed for making shopping bags or corrugated cardboard.

2. Enhancing Production Efficiency

By accurately cutting and rewinding paper rolls, these machines minimize material waste. They can handle high - speed operations, ensuring that the paper production line runs smoothly and efficiently. The ability to process multiple daughter rolls simultaneously from a single parent roll reduces the time and labor required for subsequent processing steps in the supply chain.

3. Ensuring Quality and Consistency

Paper slitting rewinders are equipped with advanced systems for tension control and edge alignment. Tension control is crucial to prevent the paper from stretching or wrinkling during the slitting and rewinding process, which could compromise its quality. Edge trimming ensures that the finished rolls have clean, straight edges, which is essential for applications where the appearance and functionality of the paper product matter, such as in printing or packaging.

The slitting process involves several precise steps, which may vary slightly depending on the type of material and the machine configuration, but the general workflow is as follows:

1. Unwinding the Parent Roll

The large parent roll is mounted on an unwind stand. The material is then fed into the machine at a controlled speed. Sensors and tension control systems ensure that the material is unwound smoothly without excessive tension that could cause stretching or damage.

2. Alignment and Guiding

Before slitting, the material is guided through a series of rollers and guides to ensure it is properly aligned. This step is essential to prevent off - center slitting, which would result in uneven daughter rolls. Laser or optical sensors may be used to monitor the position of the material and make real - time adjustments to the guiding system.

3. Cutting the Material

The actual slitting is done using cutting tools, which can be of different types. The most common are rotary knives (circular blades) that rotate at high speeds to cut through the material. The knives are positioned at the desired width intervals on a rotating shaft. As the material passes through, the knives slice it into multiple strips. Another type of cutting tool is shear blades, which operate on a scissor - like principle, suitable for certain materials that require a clean, precise cut without heat generation.

4. Rewinding the Daughter Rolls

After slitting, each narrow strip of material is rewound onto individual cores on a rewind stand. The rewind process also involves tension control to ensure that the daughter rolls are wound tightly and uniformly. The speed of the rewind shafts is synchronized with the unwinding speed and the cutting process to maintain a consistent tension throughout.

5. Quality Control and Finishing

During the slitting and rewinding process, quality control measures are in place. Sensors may detect defects in the material, such as tears or thickness variations, and the machine can be programmed to stop or mark the defective area. Once the daughter rolls are complete, they may undergo additional finishing steps, such as edge sealing or labeling, before being ready for shipment.

Slitter rewinder machines can be classified based on various criteria, such as the type of material they process, their operational complexity, and the cutting technology they employ. Here are the main types:

1. Fuselage wallboard thickness 60mm; materials: Q235, ensure high-speed stable running.

2. All rubber rollers are made of polyurethane for longtime using

3. All aluminum alloy guide rollers are processed with dynamic balance and hard oxidation.

4. All the knife shafts are made of #45 steel coated with 120μm thickness hard chrome and are processed

with dynamic balancing.

5. All electrical appliances comply with China 3C certificate standard.

1. The equipment adopts a precise cutting system and tension control system, which can ensure that the cutting accuracy and rewinding tightness reach an extremely high level, meeting the user's high requirements for product quality.

2. Through optimized design and advanced control system, HFQC-S Paper Slitting Rewinding Machine can achieve high-speed slitting and rewinding operations and improve production efficiency.

3. The equipment has a high degree of automation and can automatically complete the processes of loading, slitting, rewinding, unloading, etc., reducing manual intervention and labor intensity.

4. The equipment can handle paper rolls of various materials and specifications, with strong adaptability, which can meet the production needs of different users.

5. Germany Siemens PLC control system with touch screen brings much convenience for operator, which is easy to operate.

1. Fuselage wallboard thickness 40mm; materials: Q235, ensure high-speed stable running.

2. Equipped with a high-precision cutting system, it can achieve accurate paper roll slitting.

3. Operate through touch screen or computer interface to simplify the operation process and reduce manual errors.

4. All the knife shafts are made of #45 steel coated with 100μm thickness hard chrome and are processed with dynamic balancing.

5. Three individual servo motors synchronous control traction and duplex rewind which provides accurate web tension is calculated by PLC automatically.

1. High Precision

2. Versatility

3. Efficiency & Productivity

4. Quality Assurance

1. Paper Industry: Converts large paper rolls into smaller sizes for printing paper, tissue, and packaging, ensuring neat rewinding for easy handling.

2. Packaging Industry: Processes plastic films, aluminum foils, and other materials into widths suitable for bags, labels, and wraps, ready for packaging machinery.

3. Textile Industry: Cuts fabrics and non-wovens to specified widths for clothing, home textiles, and industrial use, with tension control protecting delicate materials.

4. Plastics Industry: Handles plastic films, sheets, and laminates for producing bags, shrink wraps, and plastic products, ensuring accurate and efficient processing.

Slitter rewinder machines are indispensable in modern industrial manufacturing. They enable the conversion of large, unwieldy rolls of materials into the precise widths needed for a vast range of applications, enhancing efficiency, reducing waste, and ensuring product quality. Whether in the paper industry, plastics, textiles, or metals, these machines continue to evolve with technological advancements, offering more automation, precision, and versatility to meet the ever - changing demands of manufacturing.

Q1: What does a Paper Slitting Rewinding Machine do?

A: It unwinds a large master roll of paper, precisely slits it into multiple narrower widths using rotary knives or razor blades, and rewinds these slit strips onto individual cores, creating smaller, finished rolls ready for further processing or end-use.

Q2: What are the main components of a slitter rewinder?

A: Unwind Stand (with tension control), Web Guide System, Slitting Section (shaft, arbors, knives/razors), Nip Rolls (optional), Rewind Shaft(s) (with tension control), Drive System, Control Panel, Core Loading/Unloading Systems (manual or automatic), Waste Extraction.

Q3: What types of slitting methods are used?

A: Razor Slitting (Shear Cut): A stationary razor blade against a rotating anvil roll. Best for lightweight to medium papers, low dust, precise cut. Most common for paper.

Crush Cut (Score Cut): Two pressurized rollers with a male/female profile. Creates a crushed edge. Less common for fine paper, used for some board or laminates.

Rotary Shear Slitting: Two counter-rotating circular knives (male/female). Used for very heavy paperboard or laminates where razor blades wear too fast.

GET A QUOTE