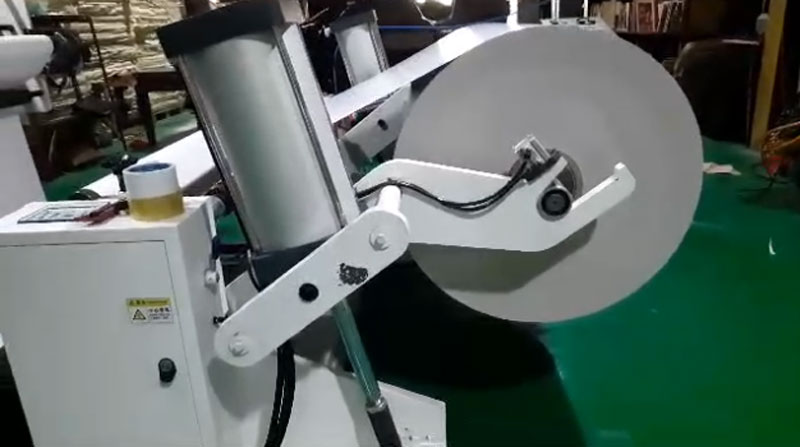

At the end of last year, We delivered one set sheeter HKZ-1400 to Sri Lanka, and because of the busy business of clients, they just have time and installed the machine last month.

They almost installed it by themselves, according to the user manual and guide video we send, After just 2 days, the machine running well.

GET A QUOTE